[Translate to English:] Lapp празднует 50-летний юбилей кабельного завода в Германии

Оскар Лапп

Oscar Lapp (1921-1987) was not only a resourceful inventor, but also a successful entrepreneur: he invented the world's first industrial control cable with color-coded veins. Thanks to the support of his wife, Ursula Ida, success was not long in coming: the new product has become absolutely indispensable in the field of mechanical engineering, instrumentation and production automation.

The innovation of the idea was also in the fact that Oscar Lapp gave his invention a brand name - ÖLFLEX® - a name that is still associated with connecting and control cables by users around the world.

We can safely say that Ursula Ida and Oscar Lapp have made history. In 1963, 4 years after the founding of U.I.Lapp KG, they opened their own production, which formed the basis of a successful family company with a worldwide reputation.

Lapp Group company, whose main office is located in the city Stuttgart, celebrated the 50th anniversary of the Lapp GmbH Kabelwerke plant on September 27 together with the company's employees, Lapp family members and many invited guests. In addition to tours of the cable factory, activities were organized for children, during which children could learn the history of the plant in a playful way. "We wanted to create a family holiday atmosphere. Ultimately, a sense of family cohesion is still one of the most important values," explained Siegbert Lapp, Member of the Board of Lapp Holding AG.

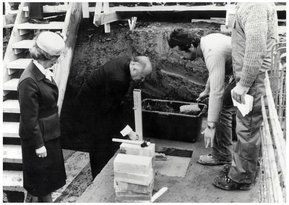

Ursula Ida and Oscar Lapp lay the foundation stone of the cable factory building at Oscar Lapp Strasse 5

The period of the early 1960s was characterized by a spirit of optimism, innovation and rapid development. After the production of ÖLFLEX® control and connecting cables was established at the production site of Wuppertal (Germany) under the name Lapp, Ursula Ida and Oscar Lapp opened their own cable factory in 1963 in a rented room on Galilee Strasse, in the city of Stuttgart. In 1965, U.I.Lapp KG moved from the residential premises occupied by the Lapp family to the industrial district of Stuttgart-Faingen, where it is located to this day. At that time, the company had 30 employees. "My parents built a company practically in a meadow. At that time, we were almost the first to start building in the now industrial area of Stuttgart-Faingen," recalls Siegbert Lapp, a member of the Board of Lapp Holding AG. Soon, the cable production moved from Galilee Strasse to its own building on Breitwiesen Strasse, which was located behind the company's head office.

Inspired by the positive results of their work, the family of entrepreneurs decided to build a new cable factory, which was opened in 1983 and located on Gewerbestrasse (currently Oskar-Lapp-Strasse) opposite the company's head office. The area of the plant is about 7,000 sq. m., of which 5,000 sq. m. are allocated for the production part. Shortly after, Contact GmbH moved to the top floor of the building, which was originally used as a parking lot. Contact GmbH is a part of the Lapp Group and specializes in the production of industrial electrical connectors. Lapp Systems GmbH, specializing in the production of cable and protective systems according to individual customer requirements, was also located in the same building.

Today, production in Stuttgart is mainly aimed at manufacturing products according to individual customer requirements

Only one factory employs 120 people – 90 in production and 30 in management. About 15,000 kilometers of cable are produced daily using the latest modern equipment. This figure is almost equal to the distance from Stuttgart to Beijing and back. In Stuttgart, the cable is manufactured according to individual customer requirements. Large-volume products with production lengths up to 100 kilometers are manufactured in Forbach, France. However, all innovative developments and processes for optimizing work are tested and implemented primarily at the production site in Stuttgart. It is for this reason that the building also houses the latest high-performance testing laboratories. Here, in artificially created conditions 5 times higher than the gravitational acceleration forces, products are tested for millions of bending cycles at maximum speeds and minimum bending radii.

Today, the company has 16 production sites around the world in addition to the Stuttgart plant.